It doesn’t seem to make much sense on the face of it.

Why would HSV go to all the trouble of sourcing a completely different engine for the GTSR W1, merely for the sake of an extra 39kW/74Nm?

The decision makes even less sense when you consider the production process requires the LSA engine be fitted in Holden’s Elizabeth plant only to be removed and replaced with the new LS9 engine when it reaches HSV’s Clayton headquarters.

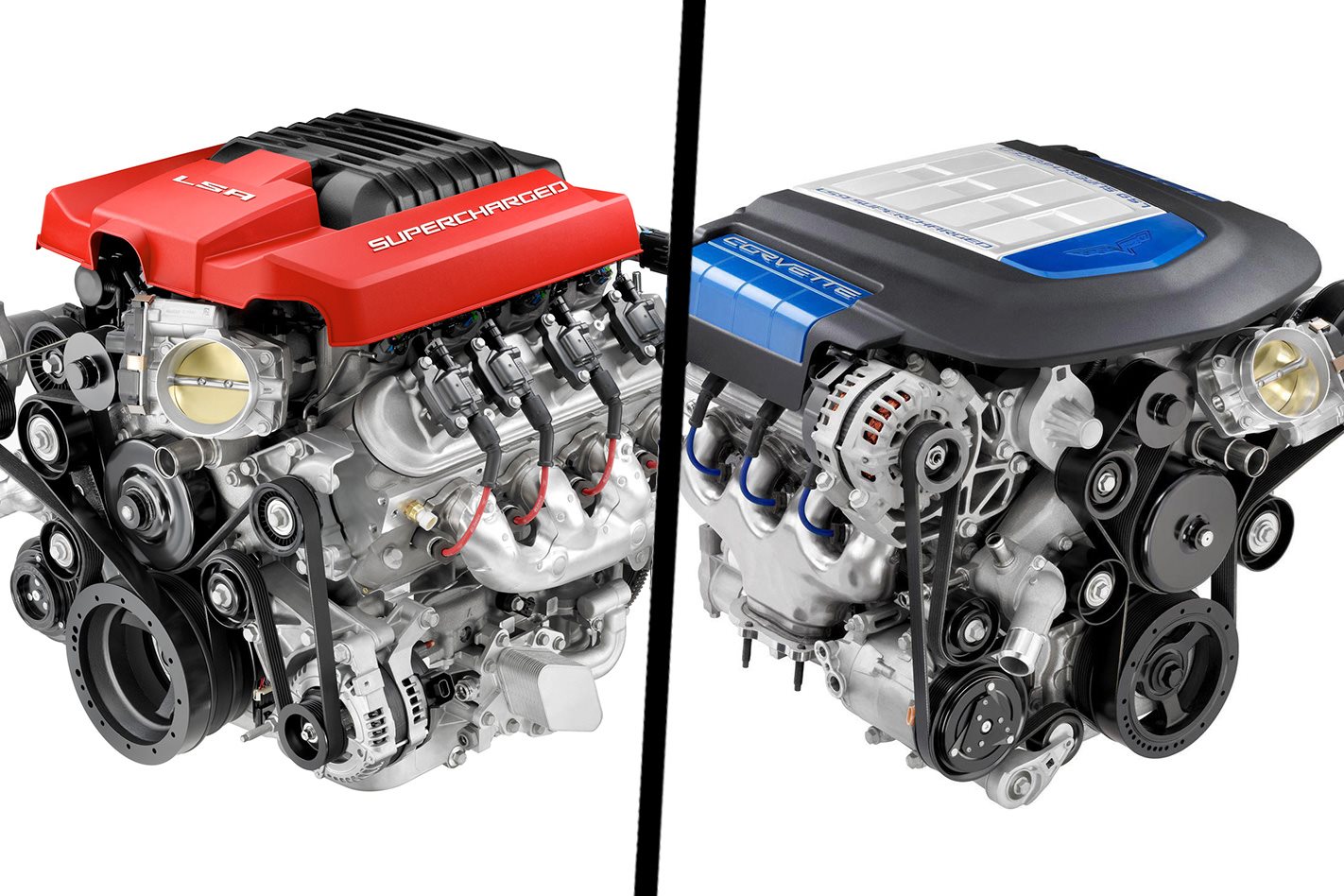

While the LSA and LS9 engines look similar on paper, dig a bit deeper and you’ll find that the 474kW/815Nm LS9 is a very different beast, with plenty of modifications which make it clear why HSV went to the effort of scouring the US for enough units to fulfil the W1’s expected 300-unit build run.

Now for the differences. The two were built in separate plants (the LS9 now having ceased production), with the LSA built in Silao, Mexico, while the LS9 came from Wixom, Michigan.

The LS9 uses a bigger 2.3L supercharger (LSA 1.9L), which allows for more boost. This means the LS9 requires stronger internals, making it safer at higher outputs than the LSA.

There’s also a more aggressive camshaft and dry-sump lubrication system, which allows the LS9 to rev to a maximum of 6600rpm compared to the LSA’s 6200rpm. Finally, a larger dual-brick intercooler cools intake charge much more effectively than the LSA’s single-brick unit.

While changing engines is an enormous amount of effort to go to, the LS9 can run more power more reliably for longer, which made it the appropriate choice for the GTSR W1.